This is a method of cutting parts on an automatic machine and reeling the parts onto a roll or sheet, this is most popular for parts that include a self-adhesive side and greatly assists customers during their production of their finished parts. It is most commonly used for labels & sticker like products.

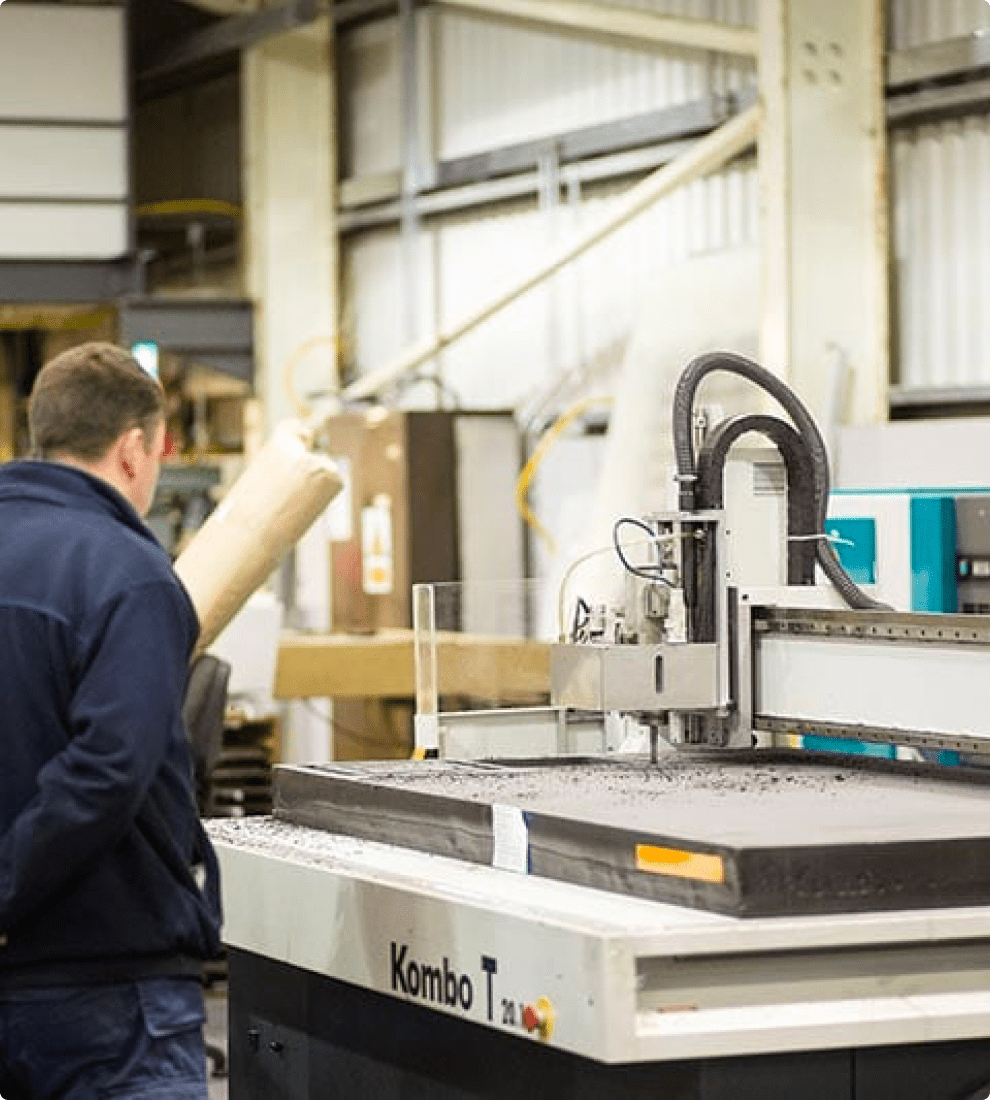

We recently invested in a new machine that not only allows the kiss-cutting of parts – but also includes a laminator – this allows us to laminate our self-adhesive material to our material or your free issue material, while also cutting the finished part. This not only reduces our production time, but also your cost for the finished parts. We can produce more intricate parts when required as we can not only kiss cut onto a roll, but we can also cut through to create holes within the finished part on the kiss cut roll – the options on this machine are endless.

This is a popular option for our some of our customers as it assists them in their production lines. Packaging can also be altered per customer, for some customers we would heat seal these into bespoke bags to ensure cleanliness for medical parts. This again can be from a small run to large runs depending on customer requirements.

All our kiss-cut products are manufactured in accordance with our quality standard ISO 9001:2015 along with specific manufacturing instructions for each part detailing specific machine, specific tooling, packaging instructions, sample parts, sample checking and test reports if required.