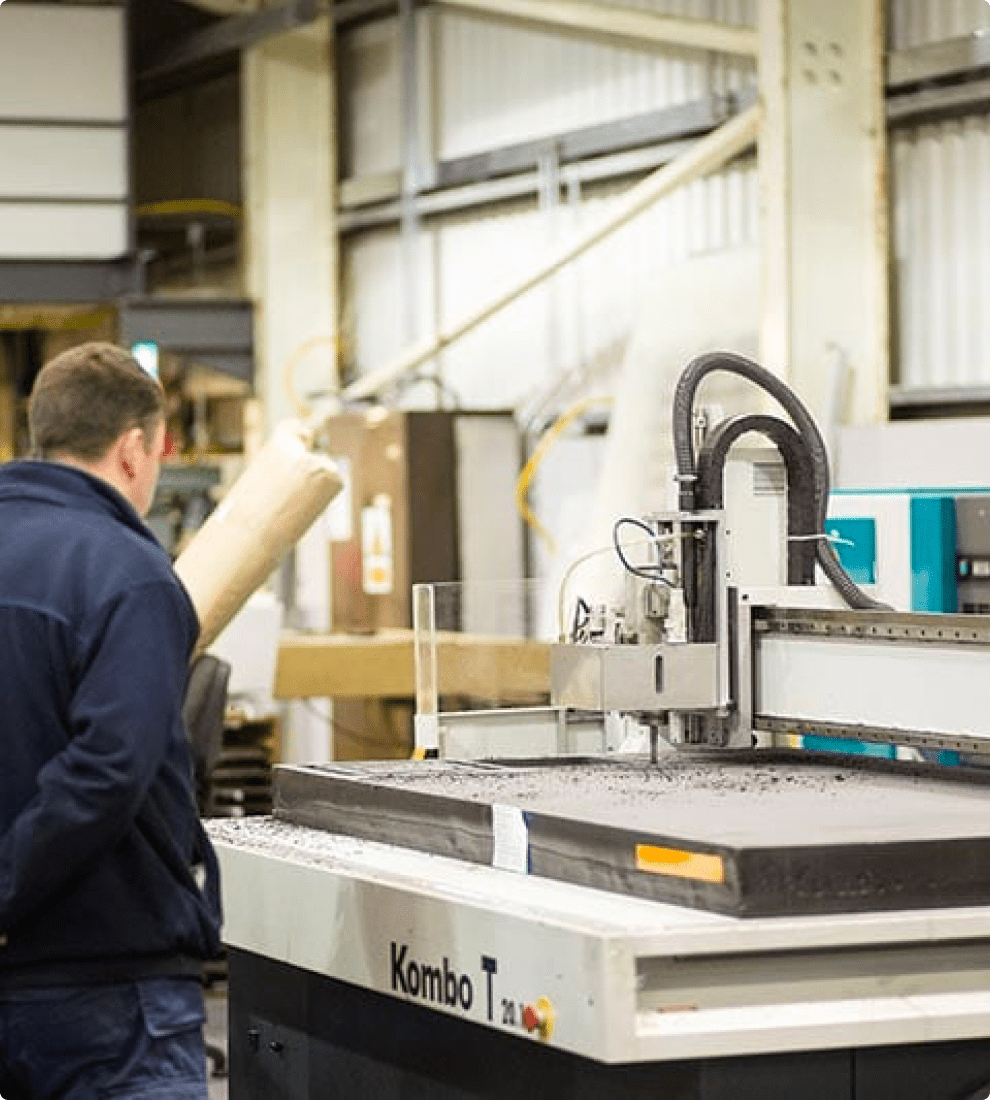

We have various automatic and manual die cutting machines ranging from small clicker press, Manual beam press’s, Automatic CNC die cutting machinery and high-speed heat sealing and kiss cutting machinery. Our machines are used for various products depending on the chosen material, size of parts and quantities being produced.

On our range of die cutting machines we can produce gaskets, strips, washers, seals, protective foam packaging and medical device components. These can be produced from materials such as Solid rubber, open cell and closed cell foam, thin plastics, thermal gap pads, graphite sheet, PVC sheeting, insulation materials, medical grade foam and all non-metallic materials. Self-adhesive options also available to be die-cut. We also cut a range of free issue materials provided by our customers on our die cutting machines some of these include PVC sheeting, medical grade foams, insulation materials and rubber belting.

The benefits of our die cutting machines include low setup times for larger production runs while having continued high accuracy cutting. If a customer requires multiple parts from one material and these can be nested together, it would allow us to cut multiple parts from one die. With cutting dies there is the potential to cut multiple layers of material to improve our efficiency – this along with nesting of parts can be very cost effective for our customers. With die cutting the tooling cost is low and usually the dies are long life, these can be made for complex and simple shapes and an provide high speed cutting on our automatic CNC machines.

We have the ability to Cutting of materials up to 25mm thick. Our Sysco machines have the ability to heat seal two materials together while cutting the finished part. We also offer a kiss-cutting service which we have detailed below. Kiss cutting and heat sealing are reel to reel using materials up to 650mm wide. with our variety of machines comes an ability to take on low and high-volume production runs based on our customers’ requirements.

All our Die-cut products are manufactured in accordance with our quality standard ISO 9001:2015 along with specific manufacturing instructions for each part detailing specific machine, specific tooling, packaging instructions, sample parts, sample checking and test reports if required.