We make all of our gaskets bespoke to our customer’s needs, delivering a high-quality finish from a range of materials every time.

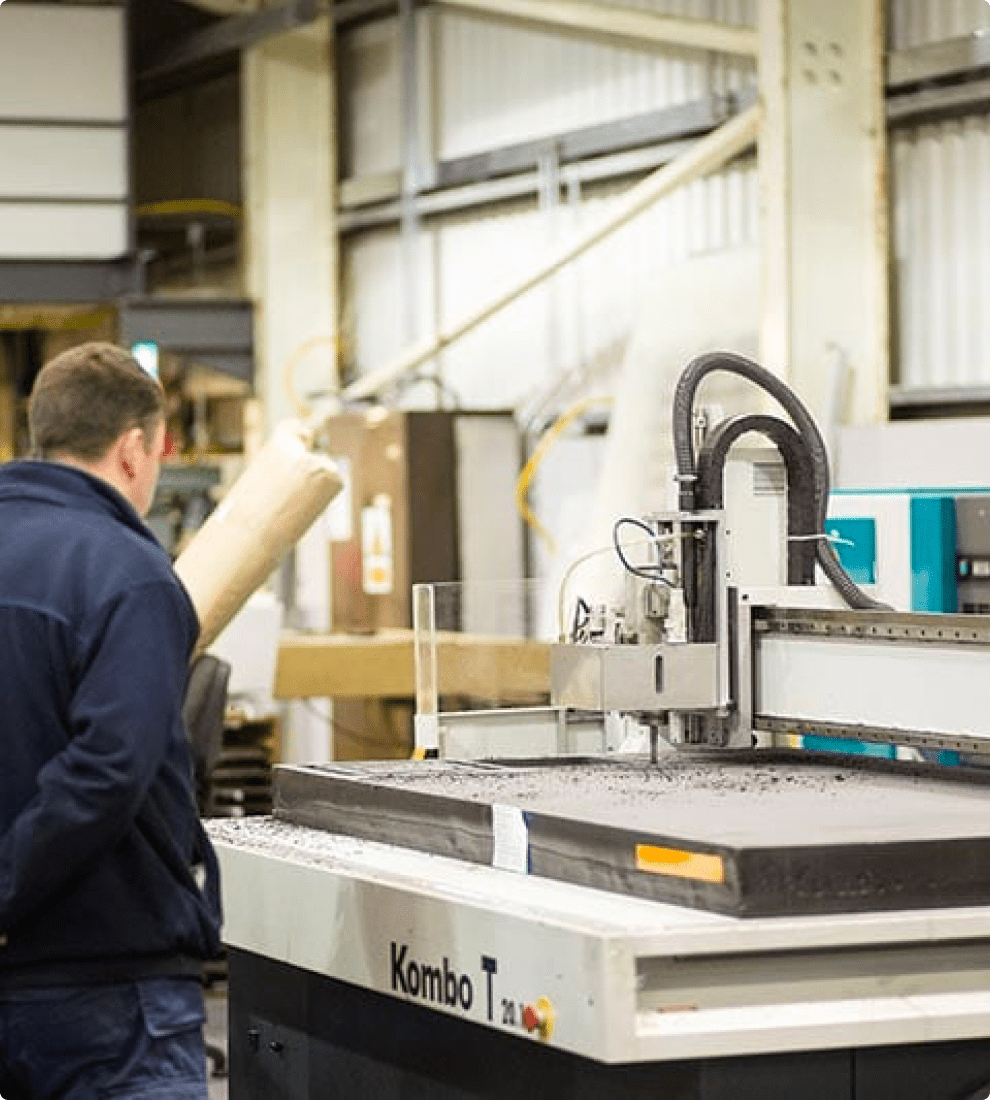

Using our specialised manual and automatic CNC machines we manufacture anything from 1 off gaskets for an emergency repair to high scale production runs – no job is too big or too small, we can even produce while you wait if needed in a hurry!

Our process to producing bespoke gaskets is easy – we use our customers technical drawing and material requirements to programme our machine and we hold most the most common gasket materials in stock in standard thicknesses. If you don’t have a technical drawing then we can simply design the gasket for you using your dimensions or sizing up the part it needs to fit.

Our machines can produce within a tight tolerance and we also offer a sample approval stage to ensure you are confident that the product completes the job before we start producing your order.

We can make any type of gasket from ring gaskets to full face flange gaskets that are sized to your exact requirements – these can be from any material requested but our standard gaskets would be from Neoprene – our most popular rubber that is oil resistant, has ozone and chemical resistance ensuring a longer life than natural rubber as it will endure the elements for longer. Or Novus 30 material is a standard material used for full face gaskets – it is widely used due as it is suitable for hot & cold water, steams, oils, fuels, gases and a wide range of chemicals and it has a maximum temperature of 225°C.

We hold a range of other materials that we can produce gaskets from in thicknesses from 0.13mm thick upwards, the options are endless with gasket manufacturing.

We have a range of customers who use gaskets in a vast range of industries from architectural to oil companies to telecommunications. Please get in touch today to discuss any requirements you might have. As ever, all of our products are produced to comply with ISO 9001:2015 with full traceability and quality assurance.