We can provide help with specialist material sourcing, proto-types, small and high-volume production runs. Material specification will be to our exact customer requirements, and we can provide full documentation for materials on request.

Previous projects include sourcing Lexan polypropylene which then had to have a scratch resistant coating applied on both sides before we could manufacture cut parts due to the high physical appearance required by our customer. We can also facilitate special production requirements e.g., one of the raw materials we use for an aeronautical customer must have a special tent erected as per the manufacturer’s instructions to prevent dust particles and keep clean whilst applying a specialist tape.

Most of the raw materials we use for this sector have special storage instructions and are stored in our raw material storage-controlled unit were the temperature and humidity are kept within a certain range.

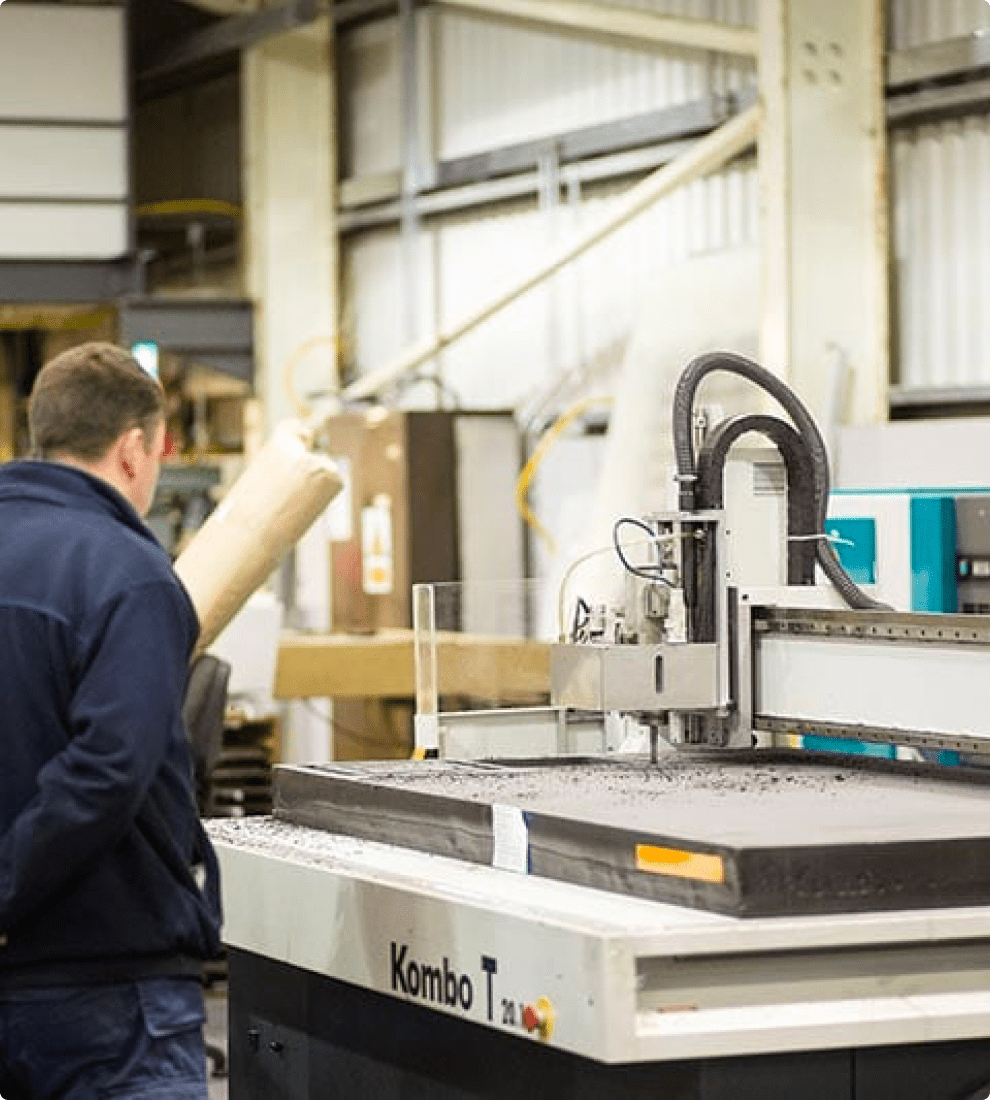

In this sector our product capabilities range from very small intricate parts made using a forged die on our automatic die cutting machine to very large specialist parts made from thin aluminium foil on our CNC machine.

All parts produced for the aeronautical industry must be produced to a very high spec with tight tolerances and we have the experience along with a proven track record from our existing customer base to deliver on this.

FAI reports are normally requested at the time of first production which are completed by Cutting Industries.

Our custom-made database provides batch number traceability throughout our entire computer system to link batch numbers from when we receive raw material right up to when we despatch our customer order which ensures electronic traceability throughout. Alongside our ISO 9001:2015 quality system which we have held since 2008 you can be assured of the highest quality parts from Cutting Industries.

With over 100 years combined experience Cutting Industries has become one of the leading manufacturers within the rubber + plastics industry