‘Excellent performance overall’

Ken - Electronics Sector

The design would be a build of various components that would all need to come together to make the end product. During this initial enquiry, the main focus was to source a self-adhesive that would not only be gentle on the skin of the patient, but also be adhesive enough to stick to skin in order to hold the medical device in place. This also has to be compliant with various worldwide regulations such as REACH, Rohs and Proposition 65. Work began on sourcing materials and prices.

Fast forward a few months and self-adhesive had been approved by the end customer and we were given the go ahead to start quoting the parts for customer. In total there were 6 different parts we would be supplying, in various forms – kiss cut on rolls, kiss-cut sheets, individual stamped components & a part with a serrated line so the end user would be able to place the device and rip the material to release the part.

To complete quotations we have to look at various factors – material, machine capabilities, any tooling or dies that need purchased, quantities of finished parts & leadtime for producing these.

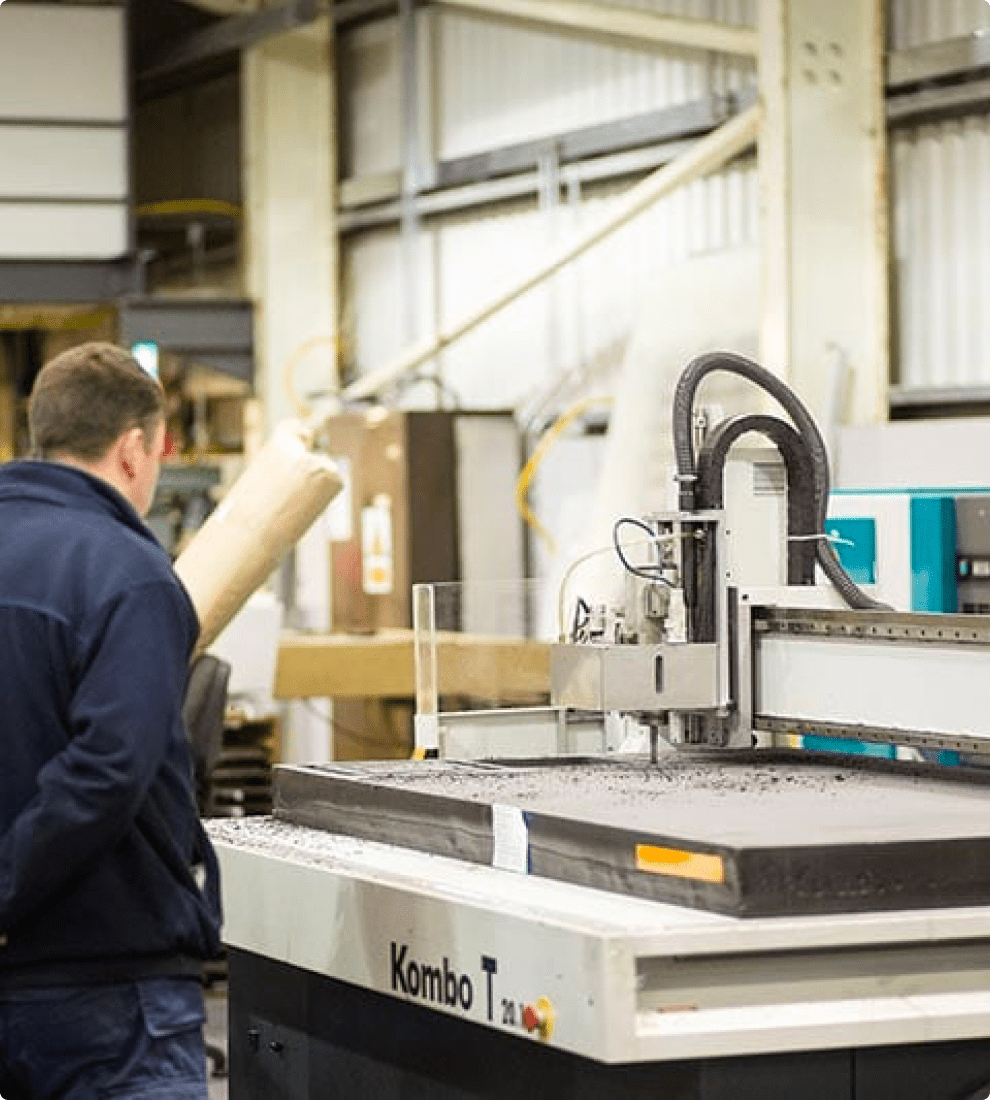

Our customer knew what materials were required for each of these parts – a mixture of their own Free Issue material that they would supply to us, some of our own material in stock, and we also utilised a local supplier for supply of a label type product. When it came to deciding what machines to use – we chose our automated Sysco die cutting machine that we purchased early 2022. This machine would not only allow us to kisscut parts onto a roll, but it would also allow us to laminate the customers Free issue material onto self-adhesive supplied by us.

When it came to looking at dies for this machine – we soon realised that to meet our customers’ requirements of kiss-cutting a number of parts onto a sheet, would involve various elements. Not only did we need to laminate the materials going onto the machine – but the cutting die needed to be able to kiss-cut the outer dimensions of the part, cut through the inner dimensions of the part and also cut through the perimeter of the die to allow us to supply these in sheet form. Again, we utilised 2 local suppliers to assist us in making this cutting die work for the customers product.

Our customer was able to give us a forecast of the quantities they would need – a few hundred for their customer to trial the finished product, a few thousand for the first supply into their customers clinics and the final order would be 2023/2024 supply of 250,000 parts. This enabled us to give our customer price breaks per quantity, allowing them to also supply end prices to their customer – advise our customer on leadtimes of raw material to us and our leadtime to supply cut parts (especially on the higher quantities) and finally to minimise any risk to supply as we had this forecast at the time of quoting.

Fastforwarding again to November 2022 and we have already supplied the first two order quantities to our customer and trials are currently being completed by their end customer. Thankfully this casestudy shows not only how our customer chain can work really well with each other, but also how multi-supplier cooperation can be utilised within Northern Ireland to supply not only customer specific products, but fully traceable, quality products to present to other companies worldwide.